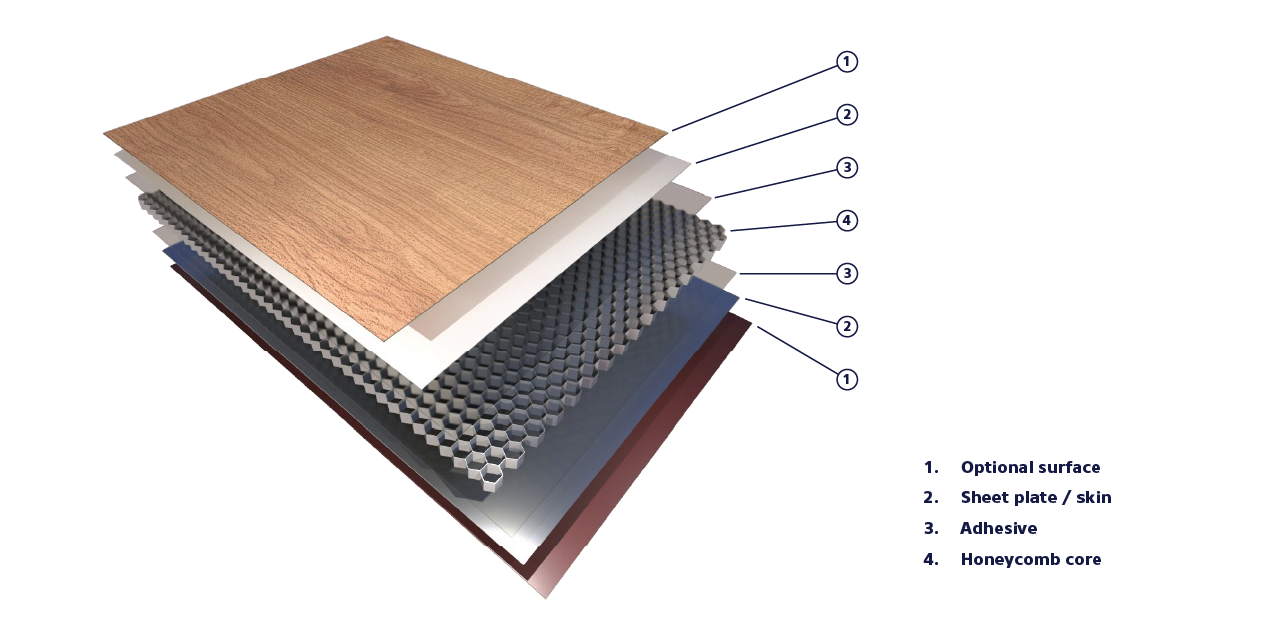

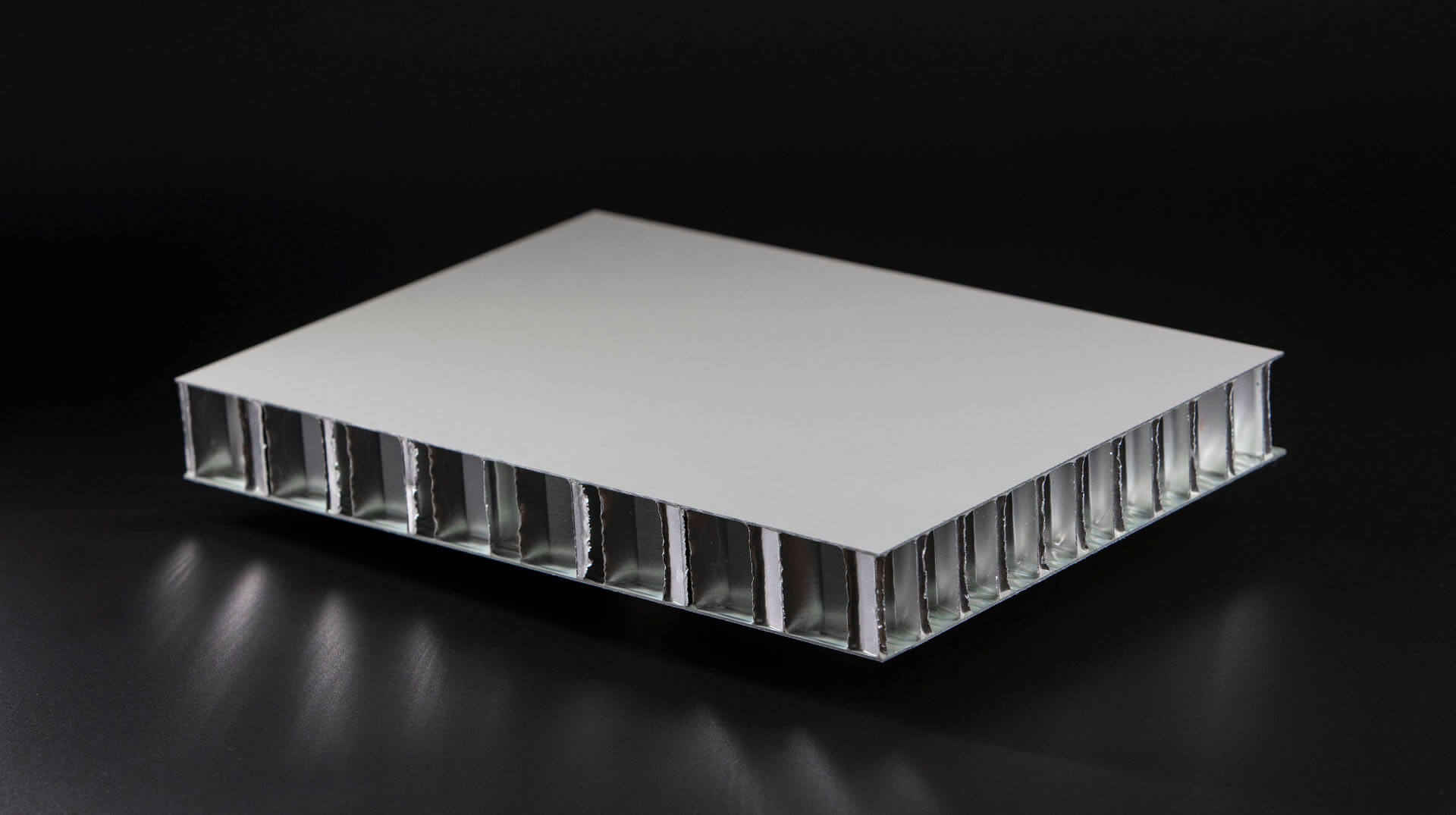

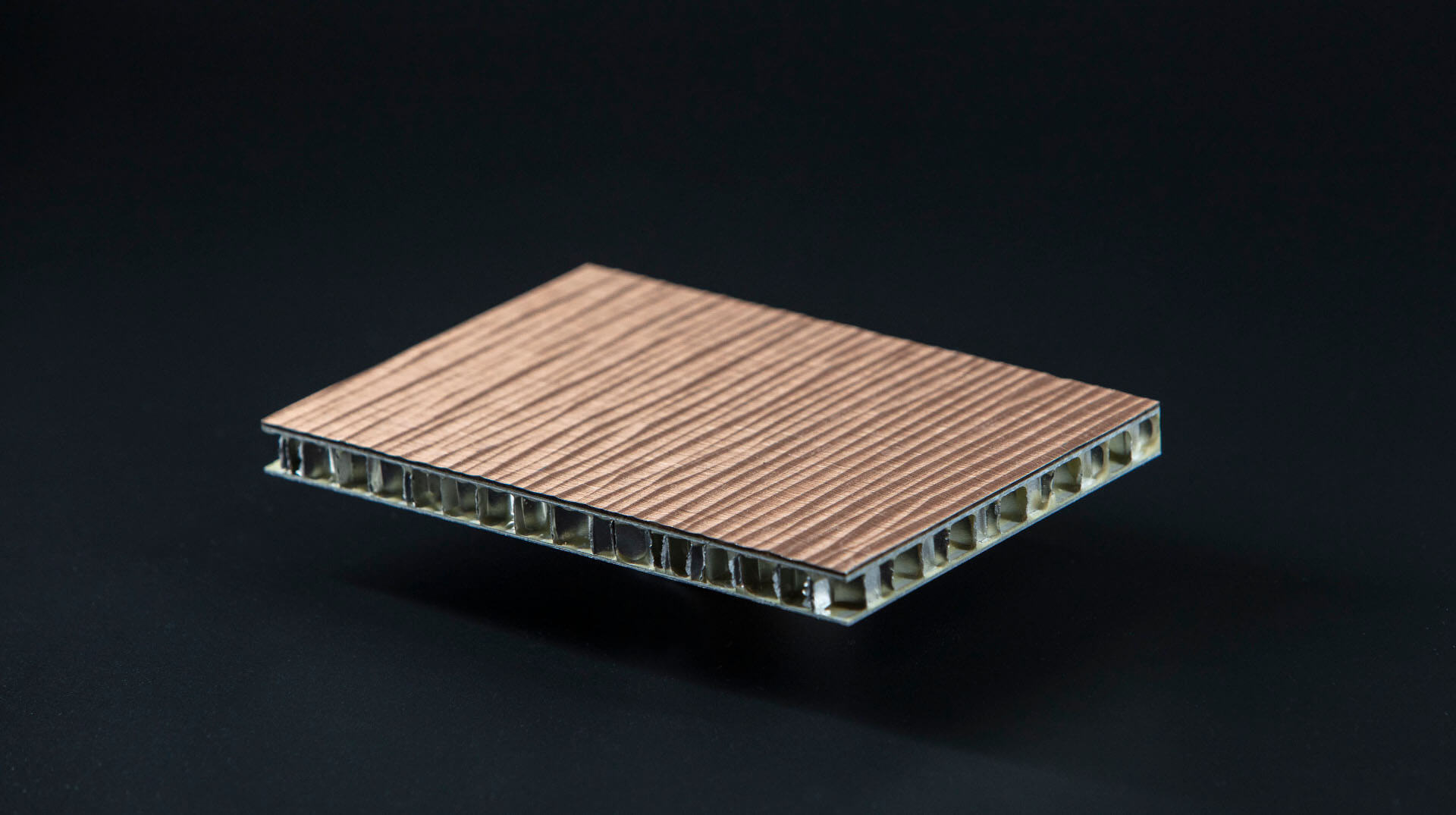

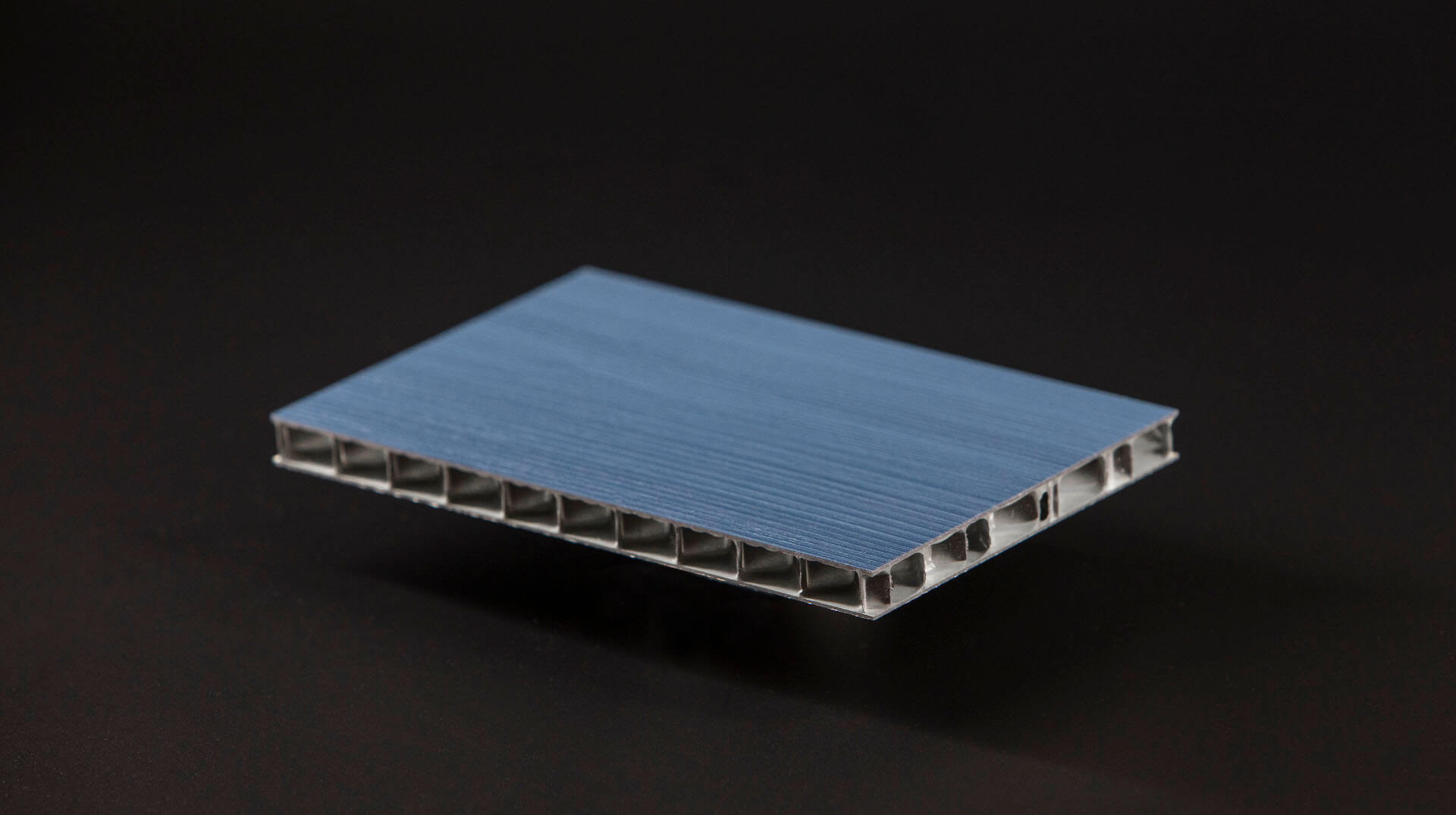

Potmacore is an environmentally friendly and fully recyclable aluminium honeycomb panel with a honeycomb core.

The lightweight, self-supporting, corrosion resistant and fire safe honeycomb panel is ideal for the supporting structures of weight-restricted applications and for module structures.

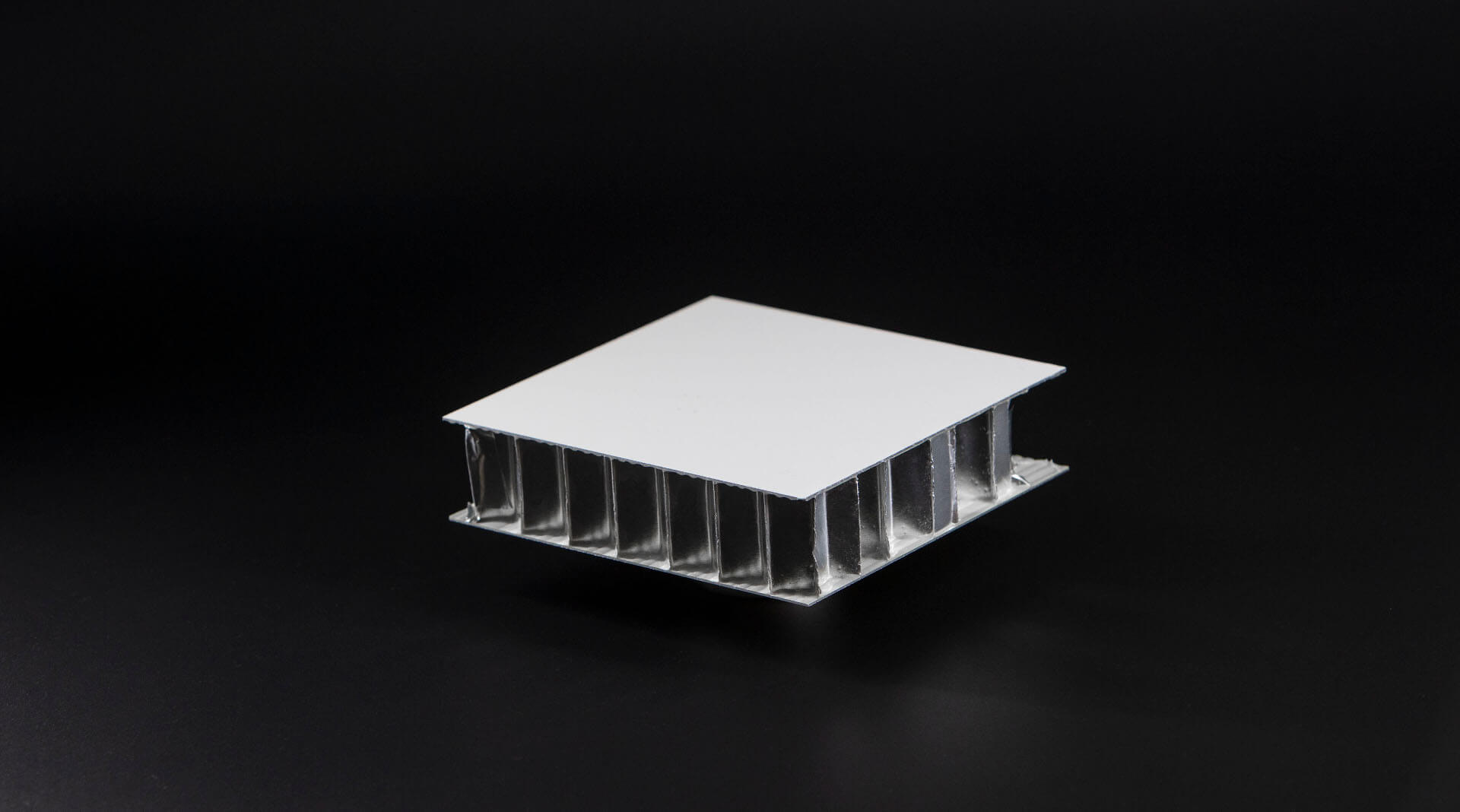

We constantly develop our products in cooperation with our customers. We can supply thicknesses (h) between 6 and 100 mm at 0.1 mm intervals to meet the specifications of each individual customer.

Deliveries with different dimensions can vary from one panel up to a delivery gross of thousands of panels with no minimum delivery requirement.

Superlight compared to traditional materials, such as wood, gypsum board, etc.

• In thickness of 10 mm ~ 50% lighter

• In thickness of 24 mm ~ 70% lighter

10 mm-thick panel ~ carries over 2,000 kg/m² equal load

14 mm-thick panel ~ carries over 3,000 kg/m² equal load

Further processing is easy and convenient using standard woodworking machines and tools.

Accurate tolerances, optimal flatness and stability with minimal thickness and big dimensions.

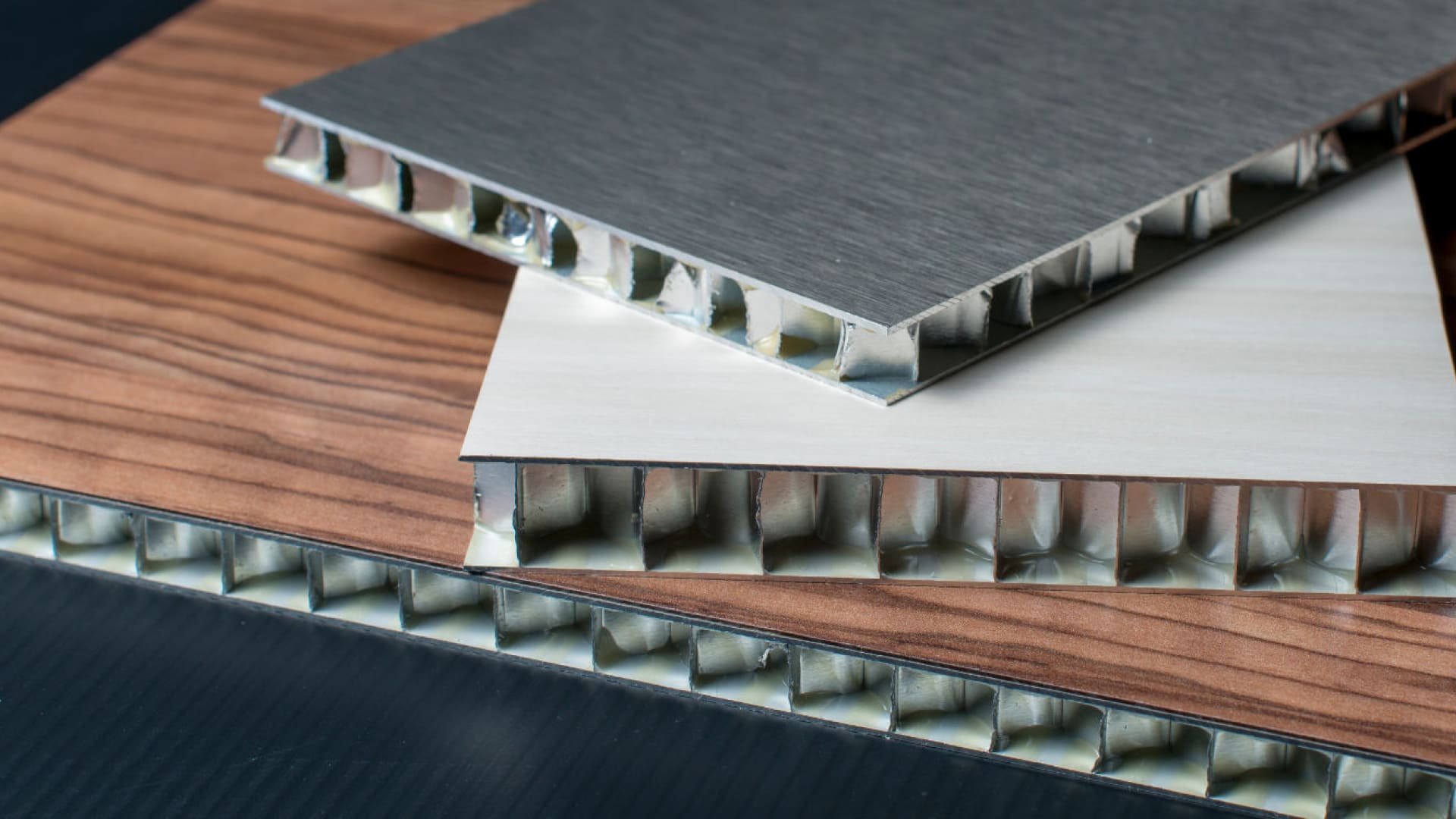

In addition to basic primer surfaces, also individual surface design through digital printing, laminating, painting, wallpapering, etc.

Technical performance and decorative finishing of the same product.

Edge trimmings, thicknesses, curve shapes and much more without any minimum order quantities – tailored for the needs of the customer.

Potmacore panels are 100% recyclable without separating the structure layers.

Pre-treated aluminium through the structure gives excellent corrosion and moisture resistance.

Also available as low carbon aluminium: ask us for more details!!

Our products and production process are certified. Regular third-party audits are an integral part of our business culture and quality management process.

Products are tested and certified on several different structure combinations to cover the needs of different customers in different market areas.

Both surfaces are coated with epoxy primer, which creates an excellent adhesion for gluing, painting etc.

Epoxy-primer coating is always provided as standard, unless another surface treatment is required.

A honeycomb panel with pre-painted surfaces with a temporary protection films. C means that both surfaces of the panel are paint coated. C/1 refers to a panel with one paint-coated and one epoxy-primed surface.

Our stock colour is RAL9010 (gloss level 30–35), whilst other colours are available upon request.

A honeycomb panel with laminated surfaces. Lhl means that both surfaces of the panel are laminated. Lhl/1 refers to a panel with one laminated and one epoxy-primed surface.

Digitally printed laminates are also available.

A honeycomb panel with PVC glued on surfaces. V means that both surfaces are coated with vinyl. V/1 refers to a panel with one PVC coated surface and one epoxy-primed surface.

Digitally printed vinyl surfaces are also available.

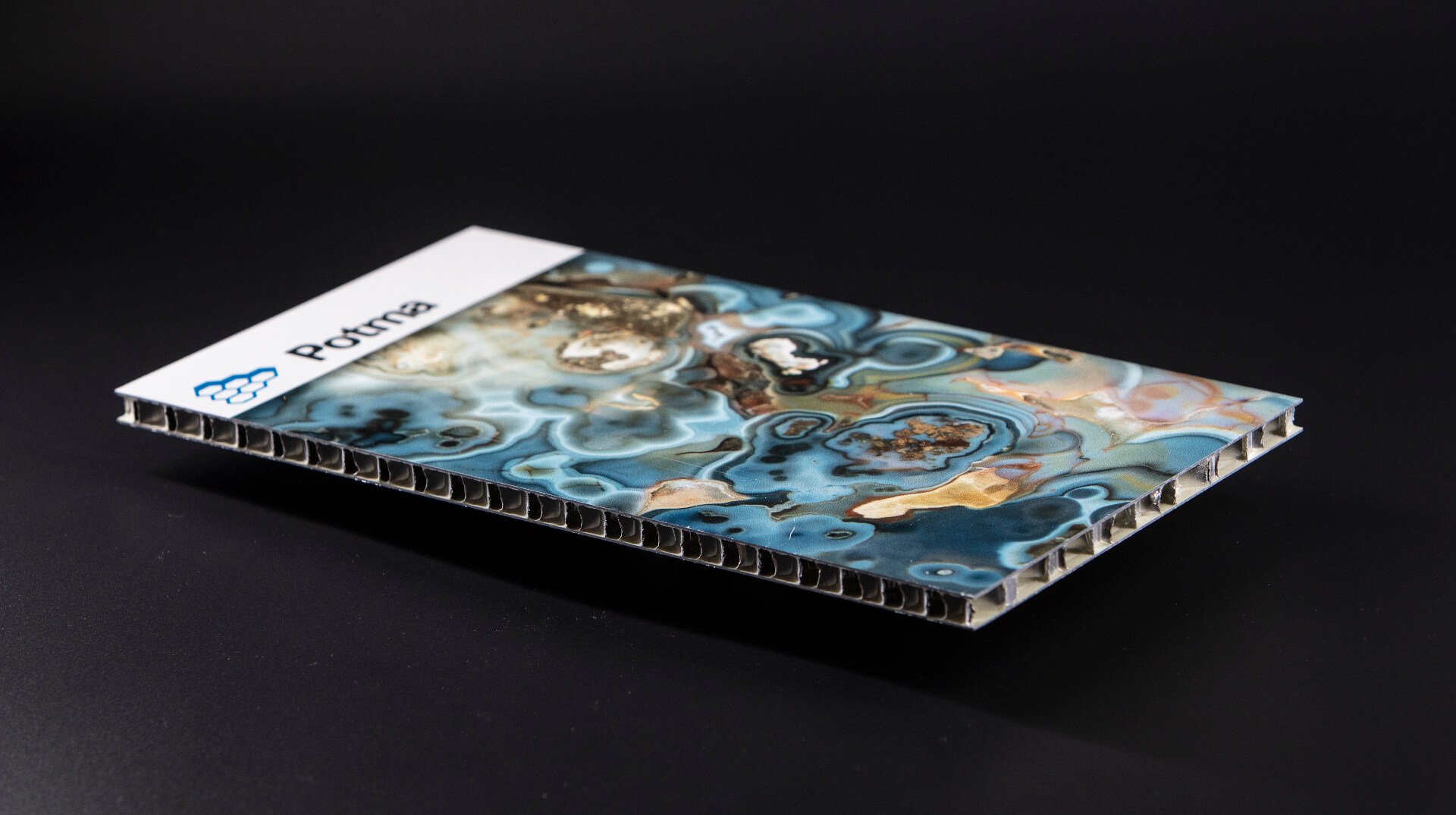

Honeycomb panel with an image specified by the customer printed on one aluminium surface.

The other surface of the panel is epoxy-primed.

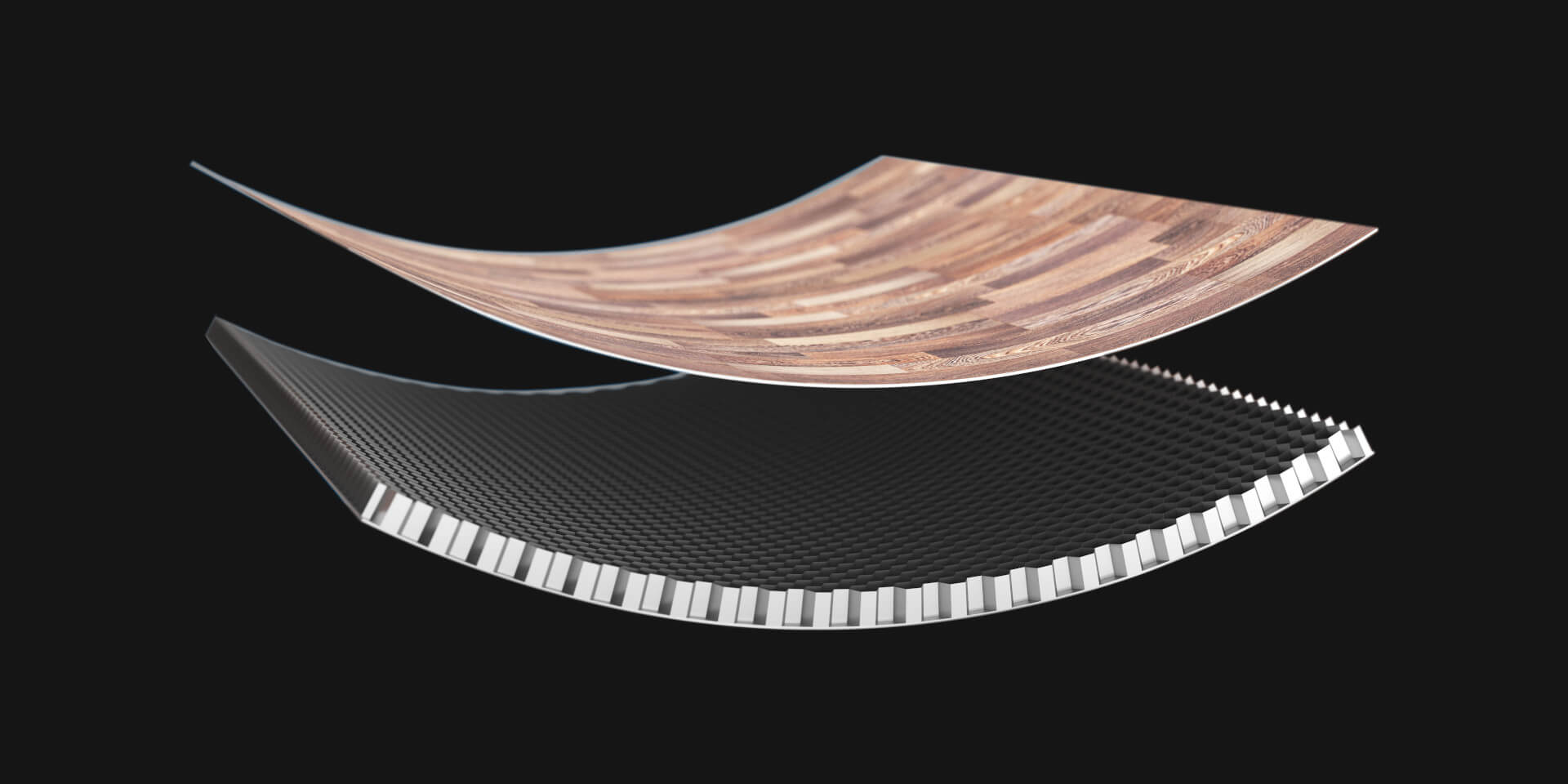

All panel alternatives are also available as semi-finished. In this case, one surface board is attached to the honeycomb core and the other is also delivered but loose.

This enables the making of curved surfaces. The semi-finished board can be bent to the required curve, after which the other surface panel will be glued in its position to create a rigid, light-weight and curved structure.

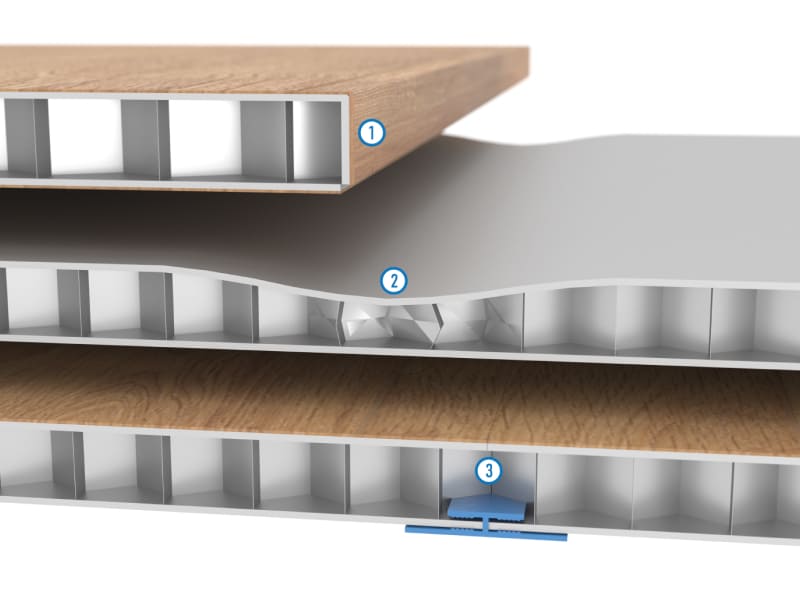

The following panel profiles are available:

Bend edge (pos. 1 in picture)

Edge thinned panel (pos. 2 in picture)

Grooved edge (pos. 3 in picture)

Edge trimming can be chosen for from one to all four edges, depending on the customer’s needs.